2023

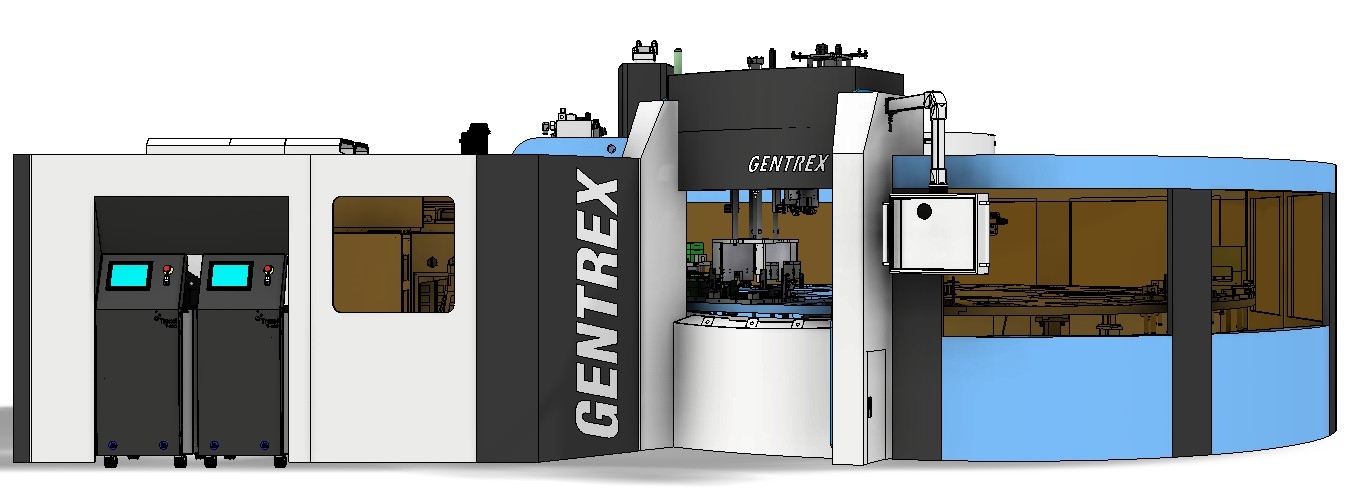

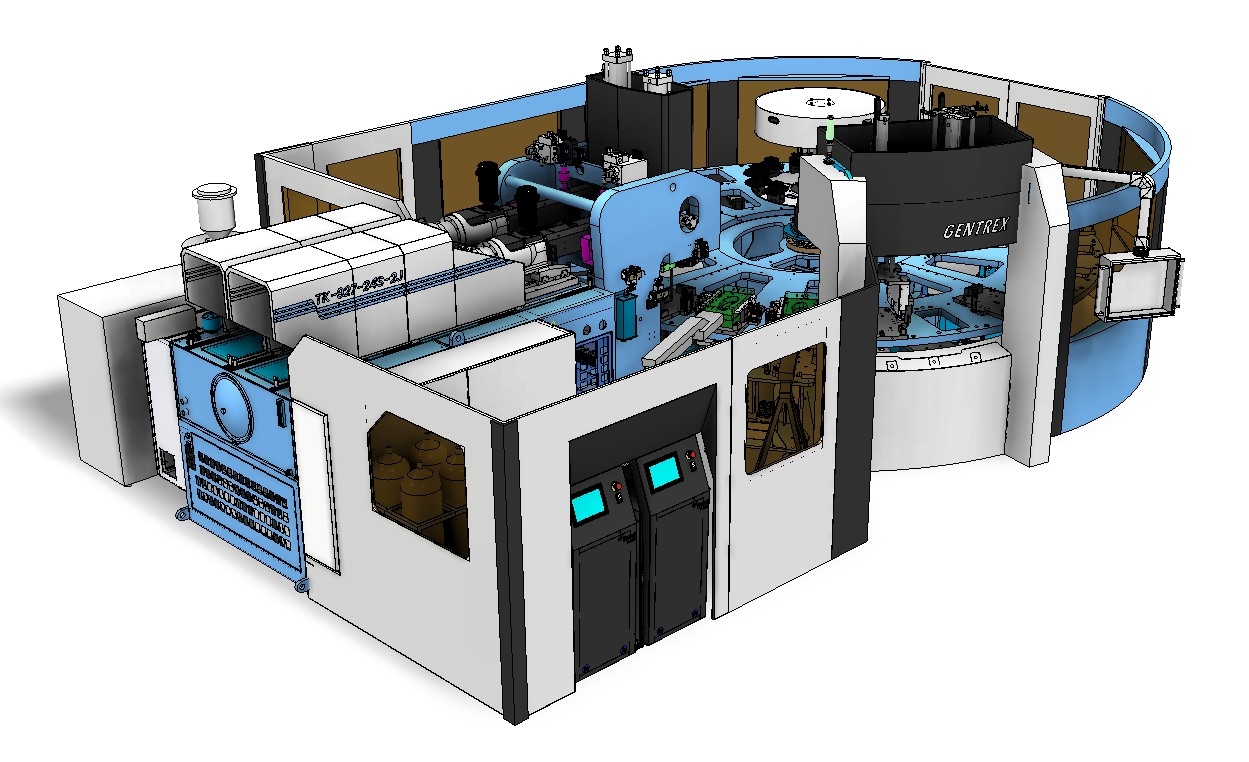

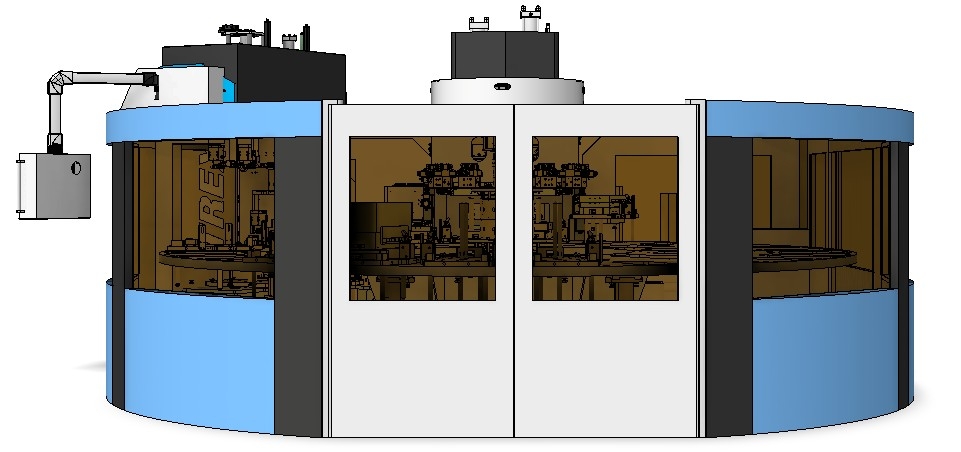

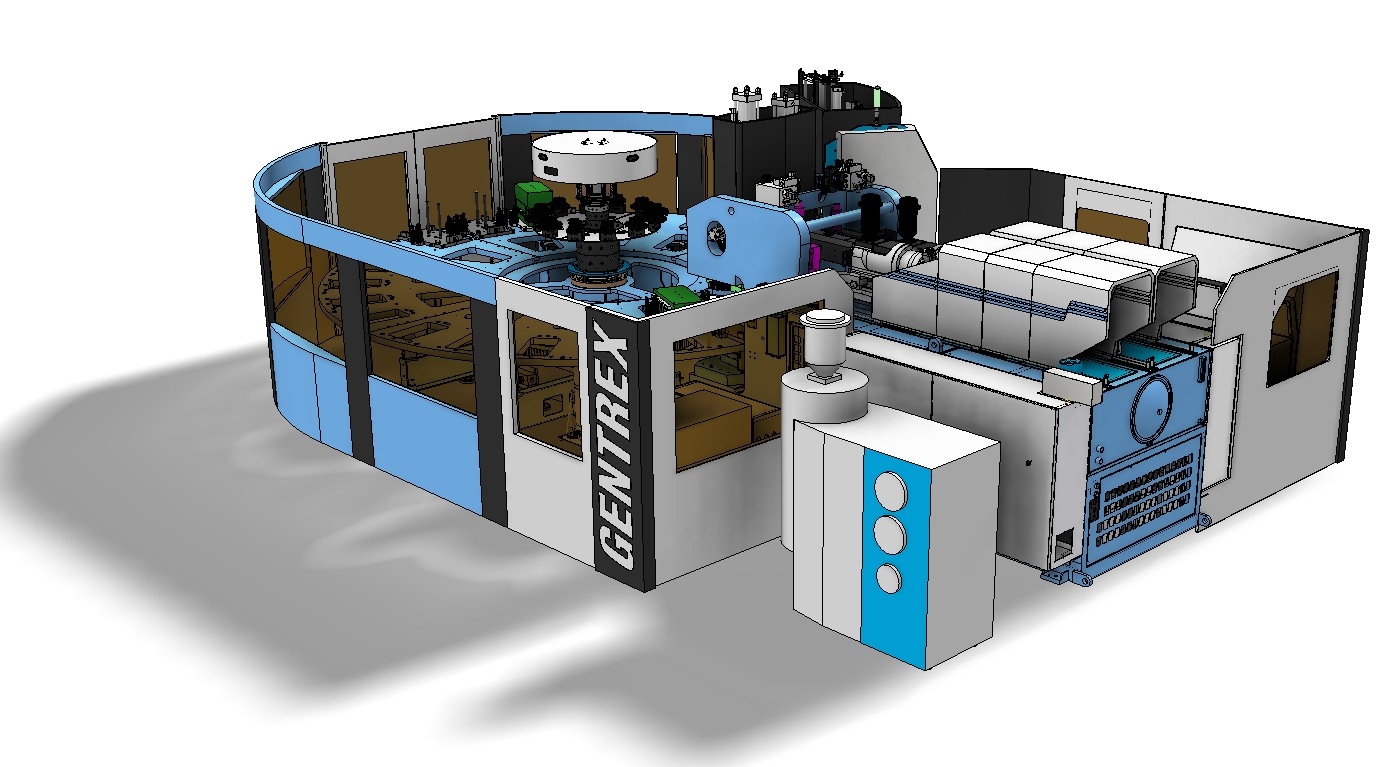

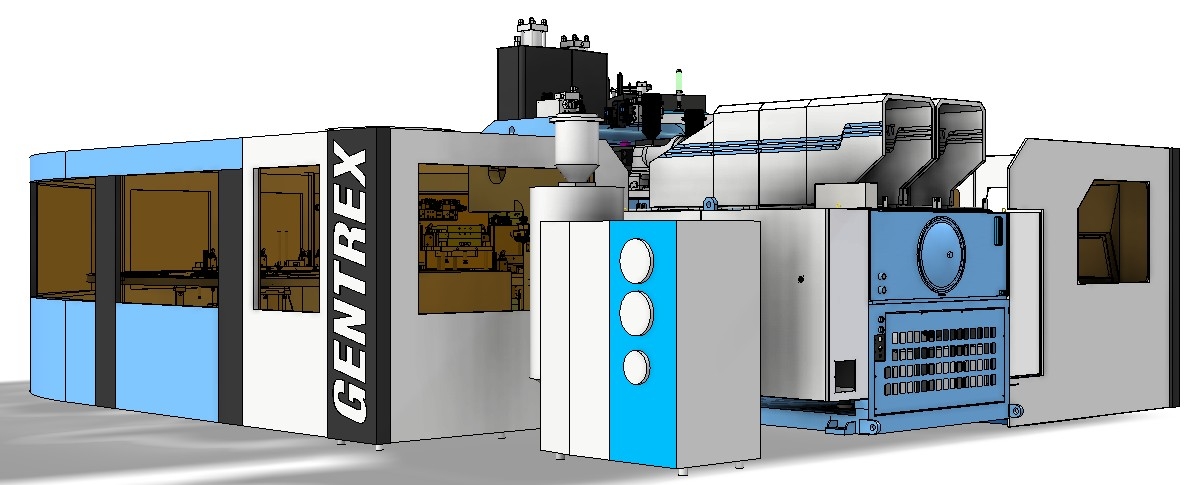

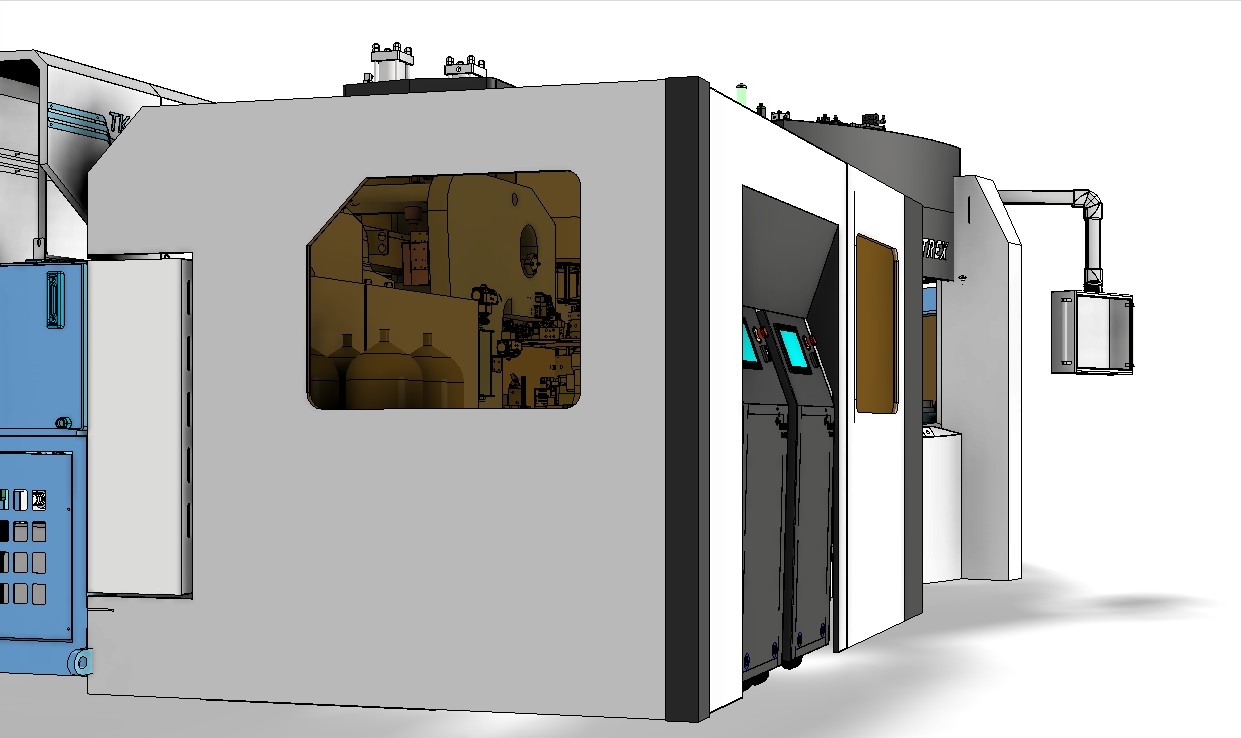

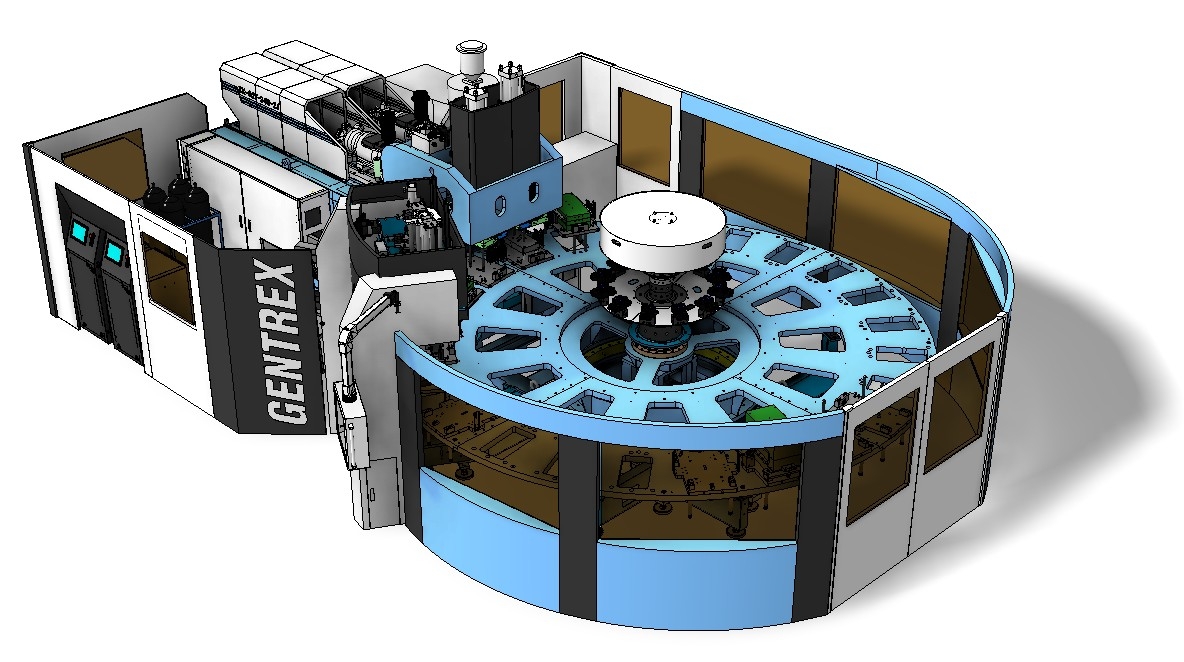

GENTREX TK-927

Entrant Company

TIENKANG CO.,LTD.

Category

Industrial, Tools & Engineering - Industrial Equipment, Machinery & Automation

Client's Name

Country / Region:

Taiwan

The world’s rapidly growing population is affecting the prosperous development of the footwear manufacturing industry; however, faced with the global massive demand for soles, the procedure of the conventional footwear industry manufacturing is not only cumbersome and lengthy, but also produces a significant amount of greenhouse gases. Based on the principles of sculpturing a future with a friendly environment and low-carbon sustainability, this product carries “multifunctional” and “sustainable” characteristics. Other than significantly shortening the manufacturing time, it further fulfilled zero-carbon emission with a supercritical physical foaming technique while using recyclable and reusable eco-friendly.

The manufacturing process of the insole of footwear is commonly chemical foaming, where the materials are unrecyclable, and the process will produce a lot of greenhouse gases including carbon dioxide and methane, where the final products cannot be recycled for reuse. This product applied the supercritical physical foaming technique, where nitrogen is compressed to become supercritical fluid to blend with the melted plastic materials, and after being injected into the mold, the phase transition is utilized to produce the gaps, allowing the finished products to accomplish diversified buffering and bouncing effects, and the products will be completed once cooled and removed from the mold. The raw materials used in the manufacturing process are completely recyclable and reusable, such that no impact will be caused to the environment even if the nitrogen of the foaming raw material is returned to nature. This product is devoted to the application of innovative and mature technologies to solve the pollution issues of conventional manufacturing procedures, while decreasing the carbon footprint throughout the process, making it a brand new proposal for net zero carbon emission for the shoe sole industry.

The conventional footwear manufacturing process requiring several processing steps will result in a massive amount of machines and complicated procedures overall. This product applies the supercritical physical foaming technology, where after being injected into the mold, the finished products will be completed after it is cooled and removed from the mold, thereby allowing the machine tools to operate independently in an area of less than 66m2.

Credits

Entrant Company

Taiwan Shin Kong Commercial Bank Customer Experience Department

Category

Communication Technology - Others

Country / Region

Taiwan